✅ 99% High-Purity Alumina – Exceptional wear resistance, high-temperature durability, and corrosion resistance, ideal for semiconductor manufacturing, electronic packaging, and precision machinery.

✅ CNC Ultra-Precision Machining – Achieving ±0.01mm tolerance, with fine grinding for an ultra-smooth surface.

✅ Factory Direct Supply – No middlemen, ensuring the best quality at the most competitive prices.

✅ Custom Manufacturing – We offer tailor-made solutions to meet your exact specifications in size, shape, and tolerance.

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

NEW110

HaoRui

custom01001

High purity alumina base with ±0.01mm CNC machining • Electrical insulation • Wear & high-temperature resistance

Certifications: ISO 9001 • RoHS

Key Specs

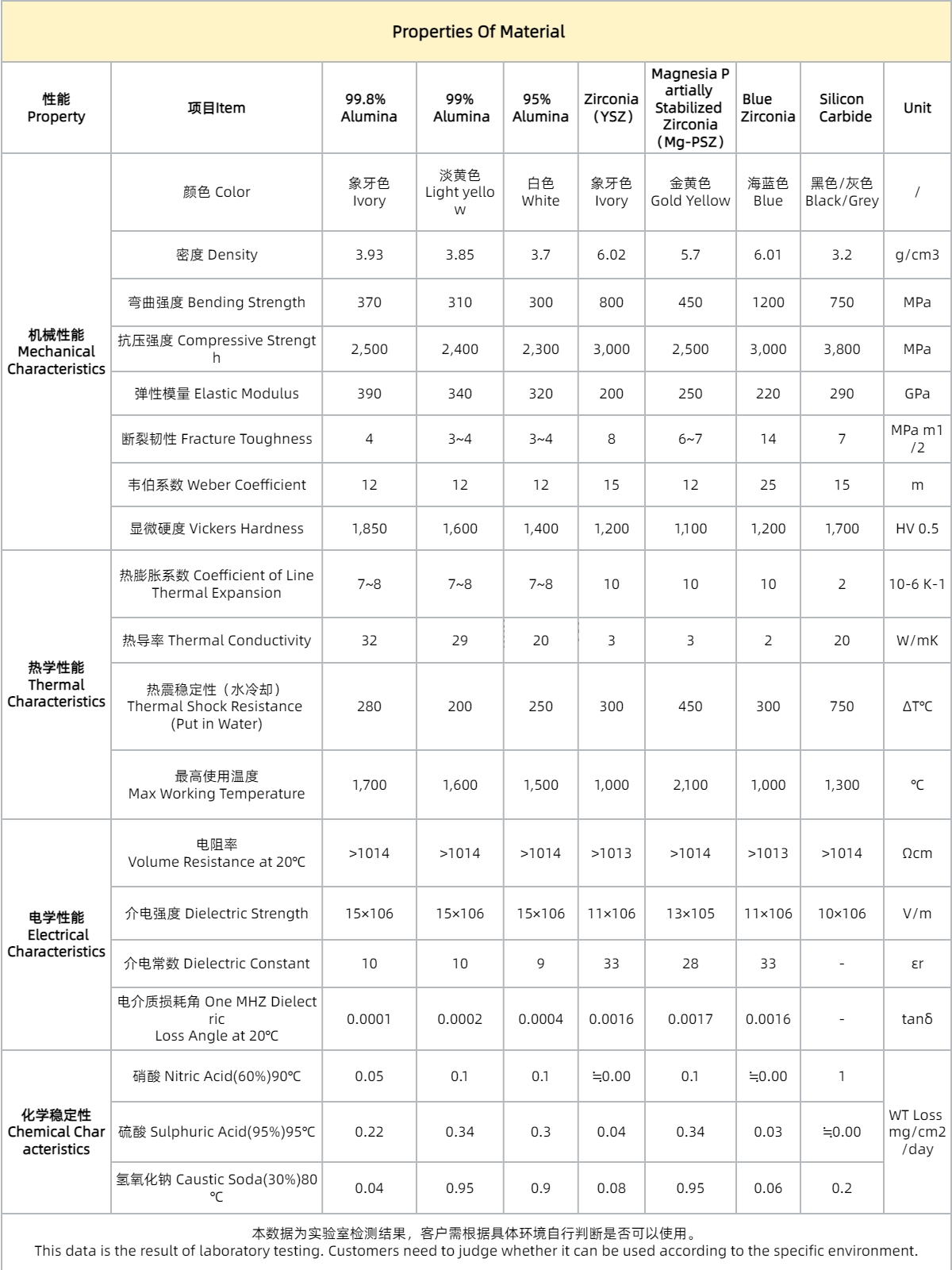

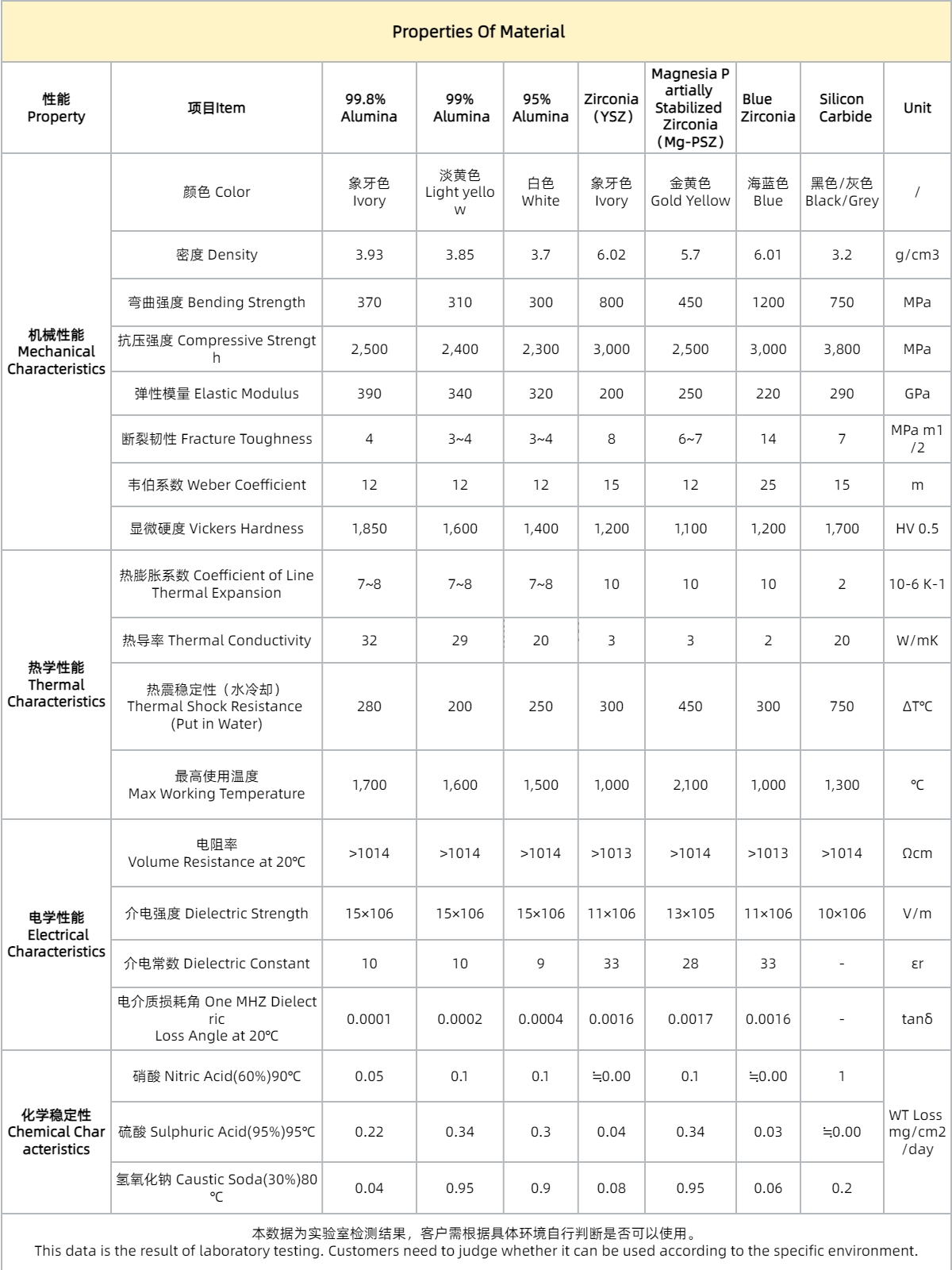

| Material | 95%–99.5% Alumina (Al₂O₃) |

|---|---|

| Tolerance | ±0.01 mm (CNC & fine grinding) |

| Surface | Matte / Polished / Mirror (optional) |

| Working Temp | Up to 1300–1650°C |

| Density | 3.7–3.95 g/cm³ |

| Lead Time | Sample: 7–14 days • Mass: 14–35 days |

±0.01mm precision for critical assemblies

Custom machining from prototypes to mass production

Electrical insulation for high-voltage equipment

Wear & high-temp resistant — ideal for furnace and mechanical parts

Our Advanced Alumina Ceramic Base is engineered for demanding industrial applications. With high-purity Al₂O₃ and precision CNC machining, it offers outstanding hardness, dimensional stability, electrical insulation, and resistance to wear and high temperatures. We support custom dimensions, tight tolerances, and surface finishing to match your assembly or fixture needs.

95%–99.5% Al₂O₃ for stable performance

CNC machining & fine grinding to ±0.01mm

Any shape, hole, or surface finish

| Property | Value |

|---|---|

| Material | 95%–99.5% Alumina (Al₂O₃) |

| Color | White / Ivory |

| Density | 3.7–3.95 g/cm³ |

| Hardness | ~1500 HV |

| Thermal Conductivity | ~20–30 W/m·K (varies with purity) |

| Dielectric Strength | High (depends on purity & finish) |

| Tolerance | ±0.01 mm |

| Surface Finish | Matte / Polished / Mirror |

Raw material selection (95%–99.5% Al₂O₃)

Pressing & sintering

CNC precision machining

Fine grinding & polishing

Dimensional & surface inspection (CMM, profilometer)

Packaging & shipping (antistatic foam & carton)

Semiconductor equipment bases & fixtures

High-voltage electrical insulators

Laser equipment supports

Furnace and high-temp components

Wear-resistant mechanical parts

Test fixture bases and jigs

1. Upload your drawing (STEP / STP / DWG / PDF) or send sample.

2. We quote within 24–72 hours.

3. Approve the sample → Production → Inspection → Delivery.

Send your drawing or sample. Fast quote & global shipping.

High purity alumina base with ±0.01mm CNC machining • Electrical insulation • Wear & high-temperature resistance

Certifications: ISO 9001 • RoHS

Key Specs

| Material | 95%–99.5% Alumina (Al₂O₃) |

|---|---|

| Tolerance | ±0.01 mm (CNC & fine grinding) |

| Surface | Matte / Polished / Mirror (optional) |

| Working Temp | Up to 1300–1650°C |

| Density | 3.7–3.95 g/cm³ |

| Lead Time | Sample: 7–14 days • Mass: 14–35 days |

±0.01mm precision for critical assemblies

Custom machining from prototypes to mass production

Electrical insulation for high-voltage equipment

Wear & high-temp resistant — ideal for furnace and mechanical parts

Our Advanced Alumina Ceramic Base is engineered for demanding industrial applications. With high-purity Al₂O₃ and precision CNC machining, it offers outstanding hardness, dimensional stability, electrical insulation, and resistance to wear and high temperatures. We support custom dimensions, tight tolerances, and surface finishing to match your assembly or fixture needs.

95%–99.5% Al₂O₃ for stable performance

CNC machining & fine grinding to ±0.01mm

Any shape, hole, or surface finish

| Property | Value |

|---|---|

| Material | 95%–99.5% Alumina (Al₂O₃) |

| Color | White / Ivory |

| Density | 3.7–3.95 g/cm³ |

| Hardness | ~1500 HV |

| Thermal Conductivity | ~20–30 W/m·K (varies with purity) |

| Dielectric Strength | High (depends on purity & finish) |

| Tolerance | ±0.01 mm |

| Surface Finish | Matte / Polished / Mirror |

Raw material selection (95%–99.5% Al₂O₃)

Pressing & sintering

CNC precision machining

Fine grinding & polishing

Dimensional & surface inspection (CMM, profilometer)

Packaging & shipping (antistatic foam & carton)

Semiconductor equipment bases & fixtures

High-voltage electrical insulators

Laser equipment supports

Furnace and high-temp components

Wear-resistant mechanical parts

Test fixture bases and jigs

1. Upload your drawing (STEP / STP / DWG / PDF) or send sample.

2. We quote within 24–72 hours.

3. Approve the sample → Production → Inspection → Delivery.

Send your drawing or sample. Fast quote & global shipping.